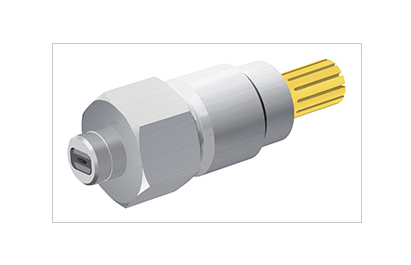

DNEX High Impact Flat Fan Nozzle

The DNEX spray nozzle is specifically made for the application of high pressure descaling steel in hot rolling mills, the purpose of the DNEX spray is to improve surface quality while reducing water consumption and operating pressures without compromising on impact force and even distribution.

The DNEX flat fan spray nozzle is used for the following applications:

- Descaling in hot rolling mills

- The highest impact force and the deepest erosion for more efficient scale removal

- Sharper spray edge definition for optimised performance

- High quality carbide orifice insert for lower wear

- Assembly comprising: Tip, Retainer Nut, Filter/Stabilizer & Weld Body

More Information

Flat Fan Spray Nozzles

Flat fan spray nozzles are a very popular spray nozzle due to the many variations and suitability for so many applications.

The spray pattern is formed using an elliptical orifice which produces an even distribution of liquid in a flat spray pattern, effectively a line of spray.

When the Flat Fan spray nozzles are installed on a header, they can provide an even spray distribution of liquid across the entire width of the product or target area, with overlapping possibilities depending on customer requirements.

Due to the design range that IC Spray offer, the flow capacity of a Flat Fan spray nozzle can be extremely low, or very high, and with large selection in between results in the Flat Fan spray nozzle being one of the most used spray nozzles.

In addition to the large flow capacity range, the Flat Fan spray nozzle (depending on the nozzle size) has a large variation of droplet sizes produced and with the ability to spray not only water, but different liquids including oils and other fluids adds to the suitability of the Flat Fan spray nozzle for so many spraying applications.

Design variations of a Flat Fan Spray Nozzle

There are two common designs to produce a flat spray pattern, an elliptical orifice as previously mentioned or a deflected type. The deflected type produces a relatively even wide flat fan spray pattern of medium sized droplets. The spray pattern is formed by liquid flowing over the deflector surface from a round machined orifice.

Flat Fan spray nozzles are available with threaded connections, or a fan tip design, this design uses a retaining nut to connect to the header.

With self-aligning flat fan spray tips, self-cleaning flat fan spray nozzles, high impact and high-pressure flat fan spray nozzles it is easy to see why this nozzle range is so popular.

FAQ

Available materials include:

- Stainless Steel Body with Tungsten Carbide orifice insert

We stock 1000s of spray nozzle products at our UK warehouse, with additional stocks at our manufacturing partners in Europe and Japan. If your required product needs to be manufactured, our specialists can assist in giving you an accurate lead time.

If your product is in stock in our UK warehouse, you can expect the below lead times:

Mainland UK and NI - Next working day

Rep. of Ireland - 2-3 working days

Europe - 3-5 working days, express shipping service at additional cost

United States of America - 3-5 working days

Rest of world - 5-7 working days

For goods that are in stock, we can despatch same day up until 13:00pm. Any orders made after this time will be despatched on the following day.

If your product is stocked at one of our manufacturers, we advise that lead times could be up to 2 weeks.

If your required product needs to be manufactured, our specialists can assist in giving you an accurate lead time.

For the majority of spray applications, low pressure is required in the range of 1-5 bar. However, for applications requiring either high flow volumes or high impact, then high pressure is used.

Within our range of products, we have high pressure materials such as tungsten carbide that operate at pressures up to 270 bar. Contact our office for further technical assistance and to identify what pressure is best for your application.

The spray nozzle material depends on several factors, including what liquid is to be sprayed, if the spray process is high temperature and what operating pressure is to be used at the nozzles.